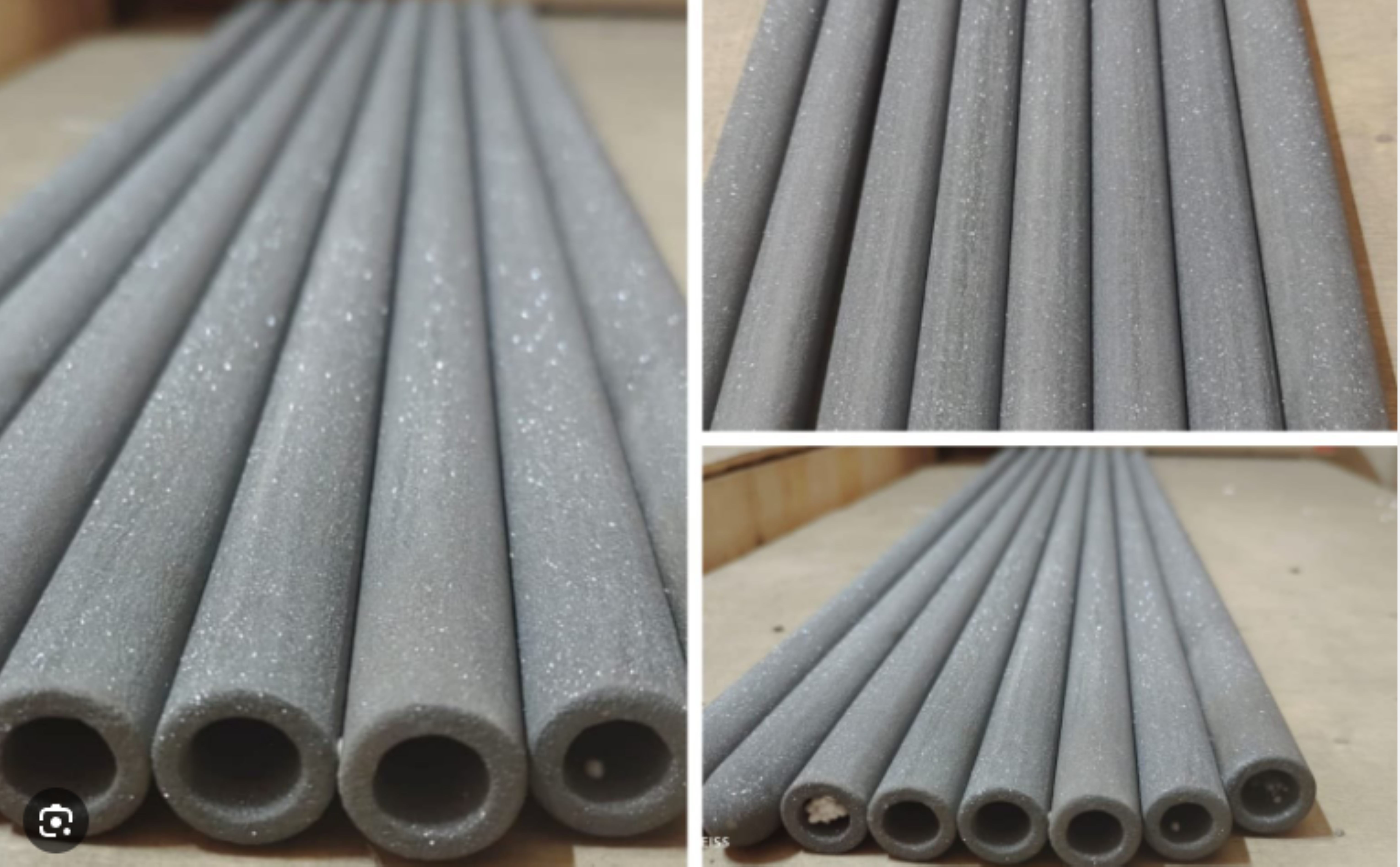

High Temperature Refactory Sic Protective Tube

Product Details:

- Size as your size

- Length as your request Millimeter (mm)

- Color grey

- Usage in medium frequency forging, various heat treatment electric furnaces, metallurgy, chemical industry, non-ferrous metal smelting and other industries.

- Product Type jx003

- Weight as your size Kilograms (kg)

- Material Specified Other

- Click to View more

High Temperature Refactory Sic Protective Tube Price And Quantity

- 5 Piece

- 15 USD ($)/Piece

- 10.00 - 100.00 USD ($)/Piece

High Temperature Refactory Sic Protective Tube Product Specifications

- round

- yes

- as your size

- Other

- jx003

- in medium frequency forging, various heat treatment electric furnaces, metallurgy, chemical industry, non-ferrous metal smelting and other industries.

- as your request Millimeter (mm)

- 220 Volt (v)

- grey

- as your size Kilograms (kg)

- yes

High Temperature Refactory Sic Protective Tube Trade Information

- dalian

- Telegraphic Transfer (T/T) Western Union

- 5000000 Piece Per Year

- 10 Days

- Free samples available with shipping and taxes paid by the buyer

- polywood case

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

Silicon carbide pipes are also known as silicon ceramic pipes, which belong to the refractory pipe familyit is crystallized from silicon nitride and silicon carbide,which has good wear resistance, heat resistance, corrosion resistance and high temperature performance. Silicon carbide pipe is the ideal lining material of smelting steel industry, because it has the advantages of high temperature resistance, good slag erosion resistance, high strength and long service life.

Application

Silicon carbide tubes are mainly used in medium frequency forging, various heat treatment electric furnaces, metallurgy, chemical industry, non-ferrous metal smelting and other industries. Widely used in metallurgical sintering furnace and intermediate frequency heating forging furnace. Length can be designed.

Features

1,Moulding:Coldisostaticpressing(CIP)

2,Sintering:GPSN/RSSN

3,Highstrengthandgoodcompactness

4,Lowthermalexpansioncoefficient

5,Excellentthermalshockresistance

6,Nowettingbymoltenaluminumandnon-ferrousmetal

7,Goodcorrosionresistance

Advantage

Silicon carbide tube with high density, impervious to water and air permeability, wear resistance, corrosion resistance, acid and alkali resistance, high temperature resistance, not easy to deformation, long life and other characteristics, can be used in copper, aluminum, zinc, alloy and other solutions! The inner diameter of the furnace hole through the siliconcarbide tube should be 1.4 to 1.6 times the outer diameter of the cold end, and the furnace hole is too small or the filling in the hole is too tight, which obstructs the free expansion of the silicon carbide tube at high temperature and causes the rod to break. During installation, when the silicon carbide tube passes through the rod holes on both sides of the furnace wall, it should be freely rotated 360 degrees to prevent forced installation and beating. Before loading the rod, an iron tube with the diameter of the silicon carbide tube can be used for trial installation. The higher use temperature of silicon carbon tube is 1600, which can not be used for a long time. The normal operating temperature is 1450 degrees

Matter Needing Attention

1, silicon carbide pipe texture is hard and brittle, thread with limited elasticity, installation and disassembly should be fully careful attention,

2, life and the use of temperature is very much related, generally in 1300ïï50ï can run 1500 working hours.

3, the heated material can not contain too much water, otherwise it will affect the life of the silicon carbon tube

4, silicon carbon tube is not suitable for working in a protective atmosphere, such as hydrogen. Thus affect the life of silicon carbide tube.

5the selection of the surface load of the silicon carbon tube changes with the temperature, and the selection of the appropriate heating power can extend the life of the silicon carbon tube.

6, the silicon carbide tube should be cleaned between the internal and external furnace tubes before installation. Remove the debris between the threads of the silicon carbide pipe or that can cause short circuit, the conductive clip connection sheet should be tightly tightened, and the insulation sheet should be reliably insulated.

7, the installation can be electric oven, long-term need not use before also must oven,

8, spare silicon carbon tube should be placed in a dry, no atmosphere erosion place, to prevent aluminized end delixing.

About Us

1.Our company is a high & new technology enterprise specially engaged in developing,manufacturing and sellingSiC (silicon carbide)heating elements and Molybdenum disilicide (Mosi2) heating elementsand silicon carbide protective pipesand carbon fiber rod

2. It established in the year 2007, with more than 16 years experience for produciton.

3. Products are exported to USA, Germany,France, Poland,Spain,Turkey, Russia, Ukraine, Japan, Korea, Singapore, Vietnam, Thailandand Iran, etc..They are highly approved by our customers all over the world.