Silicon Carbide Heating Elements for High Temperature Industry Electric Furnace

Product Details:

- Width as your request Millimeter (mm)

- Usage high temperature electric furnacesand other electric heating devices, such as in the industries of magnet, ceramics, powder metallurgy, glass, metallurgy and machinery, etc.

- Weight accord to the size Kilograms (kg)

- Height as your request Millimeter (mm)

- Product Type jx001

- Size as your request

- Length as your request Millimeter (mm)

- Click to View more

Silicon Carbide Heating Elements for High Temperature Industry Electric Furnace Price And Quantity

- 10.00 - 100.00 USD ($)/Piece

- 10 USD ($)/Piece

- 3 Piece

Silicon Carbide Heating Elements for High Temperature Industry Electric Furnace Product Specifications

- Straight type, U type, W type, and etc.

- high temperature electric furnacesand other electric heating devices, such as in the industries of magnet, ceramics, powder metallurgy, glass, metallurgy and machinery, etc.

- Other

- accord to the size Kilograms (kg)

- jx001

- as your request Millimeter (mm)

- as your request

- nature

- no

- yes

- as your request Millimeter (mm)

- as your request Millimeter (mm)

- 220 Volt (v)

Silicon Carbide Heating Elements for High Temperature Industry Electric Furnace Trade Information

- dalian

- Telegraphic Transfer (T/T) Western Union

- 100000 Piece Per Year

- 10 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- export polywood case

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- factoryt test

Product Description

The silicon carbide heating element is a kind of non-metal high temperature electric heating element.It is made of selected super quality green silicon carbide as main material, which is made into blank, silided under high temperature and re-crystallized.

silicon carbide rodis a kind of non-mental high temperature electric heating element.It is made of selected high-purity green silicon carbide as raw material which is made into blank and silicon crystal under high temperature of 2400C. It can usually make use for furnance which temperature from 600C-1600C. It is widely used in various electric heating element of glass,chemical, electronic material and so on.

Application

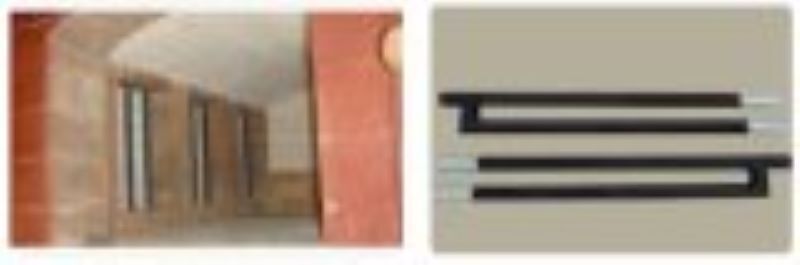

It is widely used in various high temperature electric furnacesand other electric heating devices, such as in the industries of magnet, ceramics, powder metallurgy, glass, metallurgy and machinery, etc.

ïAluminum die casting

ïLaboratory furnace

ïAluminum melting and holding furnace

ïRotary hearth furnace

ïContinuous furnace

ïCrucible furnace for non

ïGlass Feeder ferrous metals

Our Feature

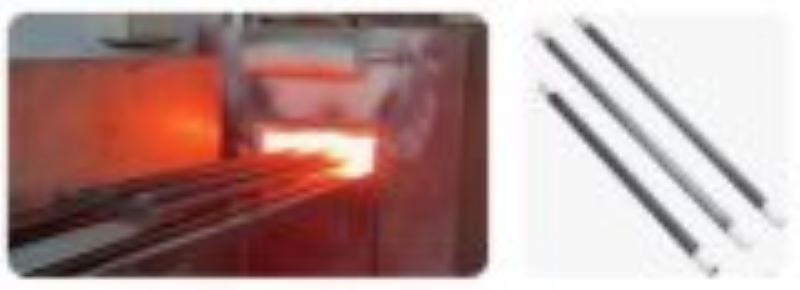

We adopt new production process of cold ends, so our SIC heating elements have excellent specific rate of heat zone resistance and cold end resistance, saving energy, long life, avoiding over-temperature of cold ends to damage the furnace body.

1 withstands as high as 1600C

2 high strength and excellent shock resistance

3 heat source is free of noise and air pollution

4 anti-oxidization, anti- corrosion

5 easy to installation and maintenance

Detailed Features of SIC heater:

1. U Type SIC heater

SIC heatersare constructed to from a U-shape. Consequently Type U have the terminals at one end for a single-phase power source. This reduces the number terminations and cold ends thus enabling energy savings.

2.W Type SIC heater

SIC heater with the terminals at one end, is designed for three-phase power source applications, such as the float glass process.

3.Spiral Type SIC heater

SIC heater with a spiral-grooved heating section, are more resistant to heat and corrosion than conventional products and are able to withstand operation in rigorous conditions. Single spiral elements are provided with energy-saving, low-resistance, cold-end terminals.

4.Double Spiral Type SIC heater

SIC heater with a spiral-grooved heating section, are more resistant to heat andcorrosion than conventional products and are able to withstand operation in rigorous conditions. Double spiral elements are provided with energy-saving, low-resistance, cold-end terminals.

5.GC ( Dumb bell type )and GD (Rod)Type SIC heater

GCand GD type SIC heater is made from high-density,high-purity silicon carbide ,which is the most popular type ofeconomical heating element capable of operating under hot and rigorous environments.

About Us

1.Our company is a high & new technology enterprise specially engaged in developing,manufacturing and sellingSiC (silicon carbide)heating elements and Molybdenum disilicide (Mosi2) heating elementsand silicon carbide protective pipes

2. It established in the year 2007, with more than 16 years experience for produciton.

3. Products are exported to USA, Germany,France, Poland,Spain,Turkey, Russia, Ukraine, Japan, Korea, Singapore, Vietnam, Thailandand Iran, etc..They are highly approved by our customers all over the world.