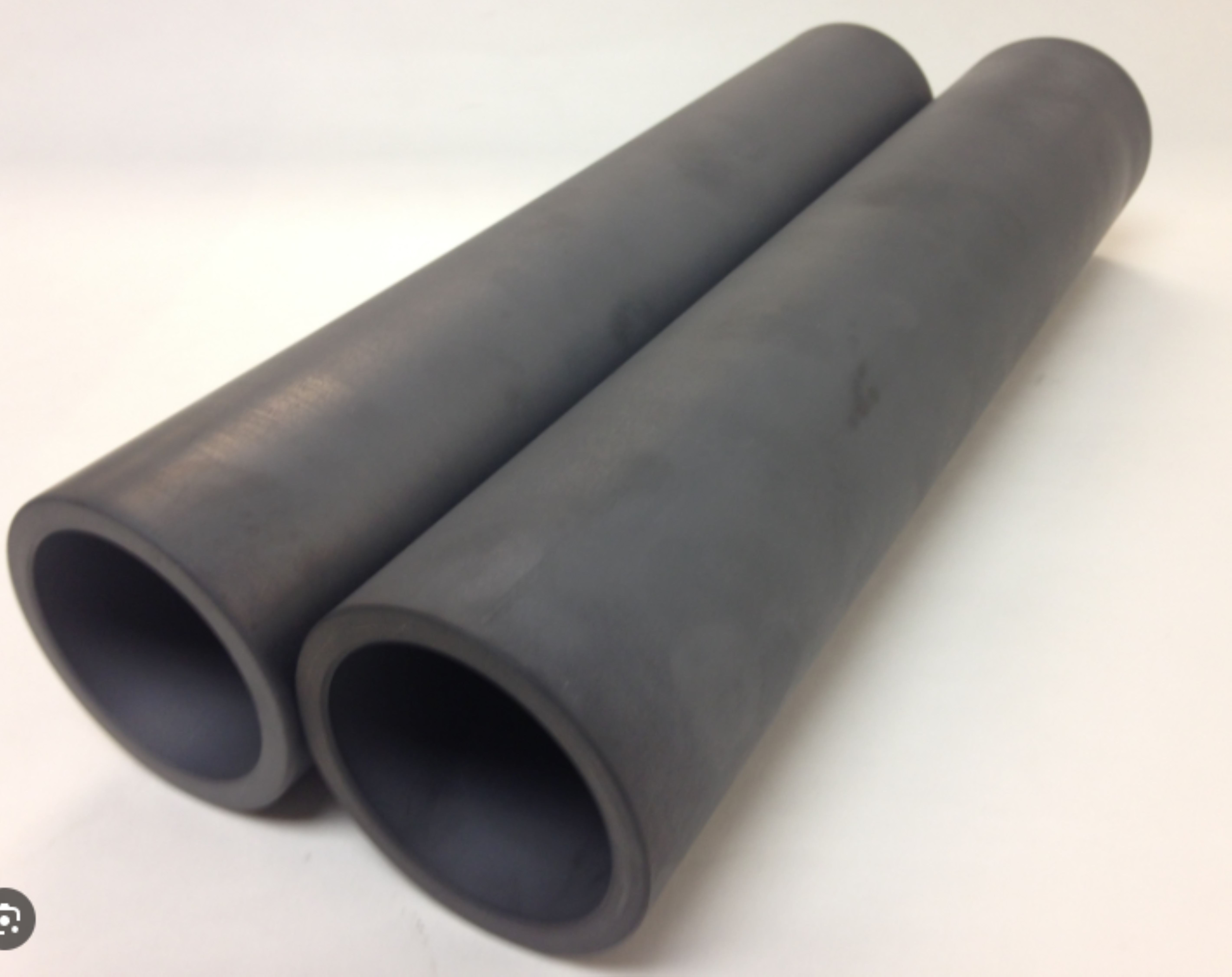

Factory wholesales High Temperature Refactory Sic Protective Tube

Product Details:

- Usage used in metallurgy, Research and production of steelmaking, glass, ceramics, refractory materials, crystals, electronic components, and semiconductor materials manufacturing and other fields, especially for high-performance precision ceramics, high-grade intraocular lenses, precision structural cermets Production of porcelain, glass fiber, optical fiber and high-grade alloy steel.

- Product Type jx003

- Size as your request

- Color grey

- Weight as your size Kilograms (kg)

- Length as your request

- Insulation Material yes

- Click to View more

Factory wholesales High Temperature Refactory Sic Protective Tube Price And Quantity

- 10.00 - 100.00 USD ($)/Piece

- 15 USD ($)/Piece

- 5 Piece

Factory wholesales High Temperature Refactory Sic Protective Tube Product Specifications

- as your request

- round

- used in metallurgy, Research and production of steelmaking, glass, ceramics, refractory materials, crystals, electronic components, and semiconductor materials manufacturing and other fields, especially for high-performance precision ceramics, high-grade intraocular lenses, precision structural cermets Production of porcelain, glass fiber, optical fiber and high-grade alloy steel.

- jx003

- yes

- grey

- as your request

- as your size Kilograms (kg)

- yes

Factory wholesales High Temperature Refactory Sic Protective Tube Trade Information

- dalian

- Telegraphic Transfer (T/T)

- 1000000 Piece Per Year

- 15 Days

- Free samples available with shipping and taxes paid by the buyer

- polywood case

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

Product Description

Silicon carbide pipes are also known as silicon ceramic pipes, which belong to the refractory pipe family. This kind of pipe is made of clay bonded silicon carbide material, which has good wear resistance, heat resistance, corrosion resistance and high temperature performance. Silicon carbide pipe is the ideal lining material of smelting steel industry, because it has the advantages of high temperature resistance, good slag erosion resistance, high strength and long service life.

SiC thermal couple protection tube is oxidation resistance, high thermal conductivity, corrosion resistance, low coefficient of thermal expansion. They can be used in metallurgy industry, chemical industry and ceramics industry. They can be used as temperature-checking protection tubes.

Feature

1,Moulding:Coldisostaticpressing(CIP)

2,Sintering:GPSN/RSSN

3,Highstrengthandgoodcompactness

4,Lowthermalexpansioncoefficient

5,Excellentthermalshockresistance

6,Nowettingbymoltenaluminumandnon-ferrousmetal

7,Goodcorrosionresistance

Advantage

Silicon carbide tube with high density, impervious to water and air permeability, wear resistance, corrosion resistance, acid and alkali resistance, high temperature resistance, not easy to deformation, long life and other characteristics, can be used in copper, aluminum, zinc, alloy and other solutions! The inner diameter of the furnace hole through the silicon carbide tube should be 1.4 to 1.6 times the outer diameter of the cold end, and the furnace hole is too small or the filling in the hole is too tight, which obstructs the free expansion of the silicon carbide tube at high temperature and causes the rod to break. During installation, when the silicon carbide tube passes through the rod holes on both sides of the furnace wall, it should be freely rotated 360 degrees to prevent forced installation and beating. Before loading the rod, an iron tube with the diameter of the silicon carbide tube can be used for trial installation. The higher use temperature of silicon carbon tube is 1600, which can not be used for a long time. The normal operating temperature is 1450 degrees

|

OD(mm) |

ID(mm) |

Length(mm) |

|

16 |

8 |

300-600 |

|

22 |

12 |

300-800 |

|

28 |

16 |

300-1200 |

|

30 |

18 |

300-1000 |

|

45 |

25 |

300-1000 |